Natural cork bark has captivated and inspired people for centuries. With its distinctive structure, inherent properties, and appealing appearance, it has found diverse applications—ranging from interior design to everyday products. While cork is often associated with simple items like bottle stoppers, this extraordinary material offers far more possibilities.

In this article, we’ll take a closer look at the texture of cork bark, its anatomy, unique features, and the wide range of uses that make it one of the most fascinating natural materials in modern design.

Table of Contents:

1. Introduction

2. What does cork bark look like? — Texture and details

3. Anatomy of cork bark — what it consists of

4. How cork bark differs from other types

5. Unique properties

6. Summary

7. FAQ

What does cork bark look like? — Texture and details

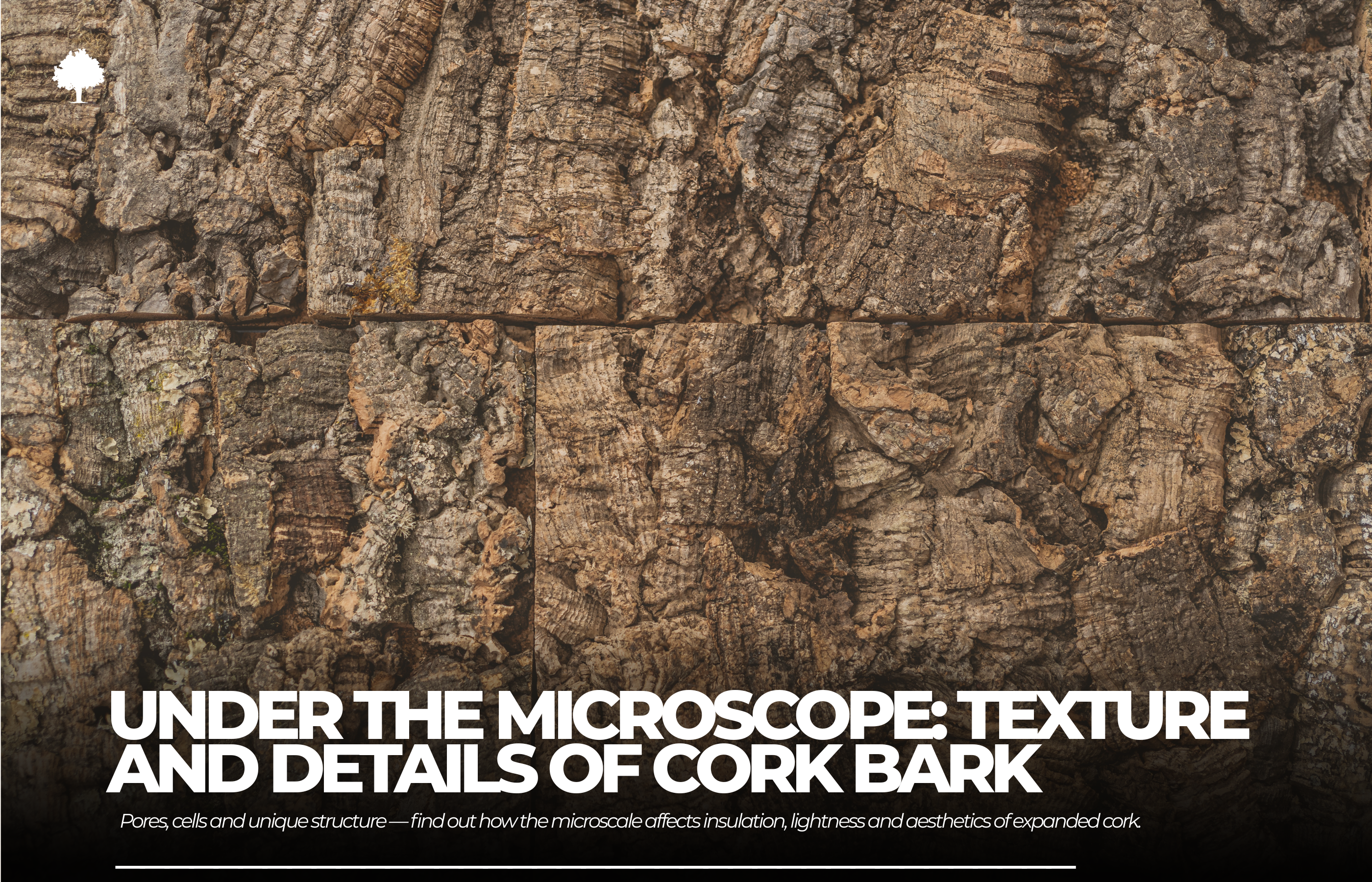

At first sight, cork bark may seem like a plain, raw material, but in reality, it is visually striking. Its surface is full of distinctive details that form a recognizable natural pattern. It is defined by irregular pores that create a textured surface, along with subtle lines and designs shaped by natural growth processes and harvesting methods.

Differences depending on age and harvesting method

The look of cork bark changes with both its age and how it is harvested. Younger layers are generally thinner and smoother in texture. Bark from mature trees is thicker and shows a more intricate pattern. When harvested by traditional methods, without the use of machinery, cork bark maintains a more authentic appearance, often marked by fine cracks and irregular air bubbles.

Microscopic details: cork under magnification

Viewed under a microscope, cork reveals a fascinating microcosm. Its structure resembles a dense network of cells forming hollow, air-filled spaces. These microscopic features give cork many of its exceptional qualities, including lightness, elasticity, and insulation. Under magnification, the uneven cell arrangement and porous texture become clearly visible—characteristics that make cork such a versatile and valuable material.

Anatomy of cork bark — what it is made of

Cellular composition: suberin, lignin, cellulose, and waxes

Cork bark has a complex cellular makeup that gives it its distinctive properties. Its main elements are suberin, lignin, cellulose, and waxy compounds. Suberin plays the most critical role, forming a protective layer that ensures water resistance, making cork resistant to moisture and weather changes. Lignin, though less abundant, strengthens the structure, adding toughness. Cellulose contributes flexibility and durability, while waxes on the bark’s surface provide extra protection against drying and external contaminants.

How cell structure shapes its properties

The cell structure of cork bark is what gives it its exceptional performance. It is made up of tiny, tightly packed cells filled with air, which makes cork extraordinarily light while still being strong. This lightness makes it ideal for a variety of applications, from flooring to insulation panels.

Cork’s elasticity comes from its ability to return to its original shape after compression. This property, often referred to as “shape memory,” makes cork highly durable, as it resists permanent deformation under pressure—one of the reasons it is so valued in flooring and furniture production.

Because of its cellular structure, cork is naturally resistant to water. Suberin, along with the unique microstructure of its cells, allows cork bark to effectively repel moisture, making it perfectly suited for humid conditions.

The role of hollow cell spaces (up to 90% of its volume!)

One of the most striking features of cork bark is the abundance of hollow cell spaces, which make up nearly 90% of its volume. These air-filled cavities are the reason cork is so light, while also providing excellent thermal and acoustic insulation. This makes cork not only extremely lightweight but also highly effective at absorbing sound and vibration, which is why it is widely used in building and furniture design. These spaces also give cork its ability to “breathe,” helping maintain a healthy indoor climate wherever it’s applied.

How cork bark differs from other types of bark

Cork bark vs. oak, birch, and pine bark

Cork bark is unique among tree barks because of its cellular structure and properties. While oak, birch, and pine bark all protect their trees, their composition does not lend itself to producing cork, which requires features such as lightness, elasticity, and resistance to moisture.

Oak bark, though strong and durable, lacks the porous structure that gives cork its lightness and insulating qualities. It is denser, less flexible, and less effective at resisting moisture, making it unsuitable for insulation or acoustic applications.

Birch and pine bark, by contrast, are much thinner, and their cells lack the abundance of air cavities that define cork. While they have uses in furniture and crafts, they do not offer the insulating or cushioning benefits required of materials in construction or design.

Why other barks can’t replace cork

The one-of-a-kind cellular structure of cork makes it ideal for a wide variety of applications, from flooring to accessories. The defining factor is the presence of air-filled cells, which give cork its extraordinary lightness, insulating ability, and water resistance. In other barks, such as oak, birch, or pine, the structure is denser and less advanced, which reduces both flexibility and insulating performance.

Cork bark also has natural resistance to fire, mold, and fungi, thanks to its complex chemical makeup, especially the presence of suberin. While other barks may offer some durability, they cannot match cork’s level of protection.

The “cork substitutes” myth — fact vs. marketing

There is a growing number of products marketed as “cork substitutes.” However, no material can truly replicate the full range of cork bark’s properties. While these alternatives are often promoted as being more eco-friendly or cheaper to produce, many of these claims are exaggerated or misleading.

Although some materials may mimic cork’s appearance, they fail to deliver the same combination of lightness, elasticity, water resistance, and insulation. Synthetic substitutes, for instance, are often not biodegradable, unlike natural cork, which is fully renewable and environmentally friendly. Cork’s natural advantages—its structure, mold and water resistance—remain difficult to duplicate artificially.

It’s also important to note that cork is harvested sustainably from renewable sources—cork oak trees can be stripped of their bark without cutting them down, making the process environmentally sound. Many so-called substitutes cannot match cork in sustainability or biodegradability.

Unique properties — rooted in its texture and structure

Natural cork bark boasts a wealth of distinctive features, all derived from its special cellular composition and design. What makes cork truly stand out among natural materials is its adaptability and exceptional qualities, making it a go-to choice for both architectural and decorative applications.

Barrier to liquids and gases

One of cork’s most valued attributes is its complete impermeability to both liquids and gases. Thanks to its air-filled cellular structure, cork efficiently blocks out moisture and various gases, making it highly resistant to dampness. This property is especially prized in construction, where it serves in insulation, wall coverings, and flooring. Beyond that, cork is used in industrial contexts whenever a reliable protective barrier is needed, such as in seals or gaskets.

Built-in fire resistance

Cork bark is naturally fire-resistant. The presence of suberin, a key chemical compound, reduces its flammability and slows the spread of flames. This makes cork particularly suitable in places where fire safety matters, such as insulation panels in homes or offices. In addition, cork does not emit toxic fumes when burned, giving it an edge over many synthetic construction materials.

Resistance to mold, fungi, and pests

Cork bark also demonstrates outstanding resistance to mold, fungi, and insect activity. Its unique chemistry, reinforced by natural waxy coatings on the surface, prevents the growth of microorganisms that might otherwise cause damage. This makes cork a reliable choice for humid environments such as bathrooms, basements, or regions with shifting climate conditions.

Exceptional elasticity and shape retention

The air-filled cellular makeup of cork gives it outstanding resilience. It can bounce back to its original form after being compressed or flattened, which is especially valuable in pressure-bearing uses like flooring or wall coverings. Its shape memory ensures long-term durability, withstanding years of wear without permanent deformation.

Warm and soft to the touch — sensory impressions

Cork also appeals on a sensory level. It feels warm and soft, creating a sense of comfort that enhances the user experience. Unlike other natural materials that can feel cool, cork conveys a cushioned warmth, making it an excellent material for floors, wall panels, and decorative interior pieces.

Where cork bark is used

With all of these advantages, natural cork is used to manufacture a broad spectrum of products. It is shaped into wall panels that excel in both sound and thermal insulation, perfect for areas where acoustic comfort is a priority. It also finds its place in flooring that blends functionality with design, providing warmth and underfoot comfort. Beyond structural uses, cork is popular in lifestyle products such as bags, wallets, and home décor pieces—valued not only for their durability but also for their eco-friendly qualities.

Summary

Cork bark is defined by its distinctive textures and fine detailing. Its irregular pores, natural lines, and organic grain make it highly aesthetic and photogenic—a favorite in interior design and decorative work. Differences in its look, shaped by age and harvesting methods, add even greater individuality, producing unique patterns that are captivating on both large and small scales.

FAQ

1. What is cork and where does it come from?

Cork comes from the bark of the cork oak (Quercus suber), native mainly to Mediterranean regions. These trees naturally regenerate their bark, allowing it to be harvested repeatedly without harming the tree.

2. How is cork bark harvested?

Cork bark is traditionally stripped every 9–12 years. To preserve the health of the tree, harvesting is done by hand, enabling the bark to regrow naturally. The tree remains intact, ready for future harvests.

3. Why is cork so lightweight?

Cork’s extraordinary lightness comes from its cellular design, made up mostly of hollow, air-filled spaces. This porous structure gives it its low weight while still maintaining strength and durability.

4. Is cork an environmentally friendly material?

Yes, cork is a fully sustainable material. It comes from renewable sources (cork oaks are never felled), is biodegradable, and can be reused. What’s more, the harvesting process preserves the trees, supporting the health and longevity of cork oak forests.

.png)