LISEC is a globally renowned name among glass manufacturers. Established in Austria in 1961, the company has spent decades setting benchmarks in flat glass processing, cutting, and production automation. Its innovations are integral to modern glass processing facilities—ranging from precision-engineered machines to advanced software for managing entire production lines.

So, what does natural cork have in common with foam? In this article, we’ll explore this intriguing connection in detail.

Table of Contents

1. Introduction

2. What connects natural cork-foam tape and LISEC?

3. Glass under protection – challenges in transport and storage

4. How natural cork-foam tape aligns with LISEC’s philosophy

5. Applications in practice

6. Why quality pays off

7. Summary

8. FAQ

What connects natural cork-foam tape and LISEC?

The answer is straightforward—glass. It serves as the common thread linking LISEC’s cutting-edge technologies with a seemingly modest yet vital component—natural cork-foam tape. Both operate in the same environment—one defined by precision, sensitivity, and an unwavering dedication to quality.

LISEC – a pioneer in automated glass processing

LISEC stands as a global leader in automated glass production. For over six decades, the company has developed integrated systems covering every step of manufacturing—from cutting and sorting to edge finishing and the assembly of insulated glass units.

Through continuous investment in innovation and development, LISEC defines industry standards for precision and efficiency. Its equipment and software are meticulously designed to maximize accuracy while minimizing material waste—an essential advantage in the demanding world of glass production.

The company’s philosophy revolves around automation, reliability, and the protection of finished products. This makes LISEC not merely a supplier but a true partner in the pursuit of perfection. The brand understands that even the smallest scratch, microcrack, or misalignment can compromise the entire process—which is why every innovation aims to safeguard the glass and elevate the final result.

Here’s where natural cork-foam tape comes into play—a modest yet highly effective component that shares the same mission as LISEC’s technology: keeping glass in perfect condition.

Glass under protection – challenges in transport and storage

Glass is a material that combines strength with fragility. Even minimal stress, a tiny fracture, or improper pressure can ruin a flawlessly processed sheet. This is why transportation and storage are among the most delicate and critical stages in the entire production cycle.

Challenges: microcracks, scratches, and material loss

Once processing is complete, glass sheets are typically stacked—one atop another. Every glass-to-glass touchpoint poses a risk of scratches, chipping, or microcracks that might not be visible at first glance. Over time, these imperfections can result in breakage during handling, transport, or installation.

Moreover, improper separation—without the use of suitable spacing or cushioning—increases the likelihood of waste and customer complaints, which for large-scale glass producers can mean significant financial and logistical losses.

Natural cork-foam tape – a small detail that makes a big difference

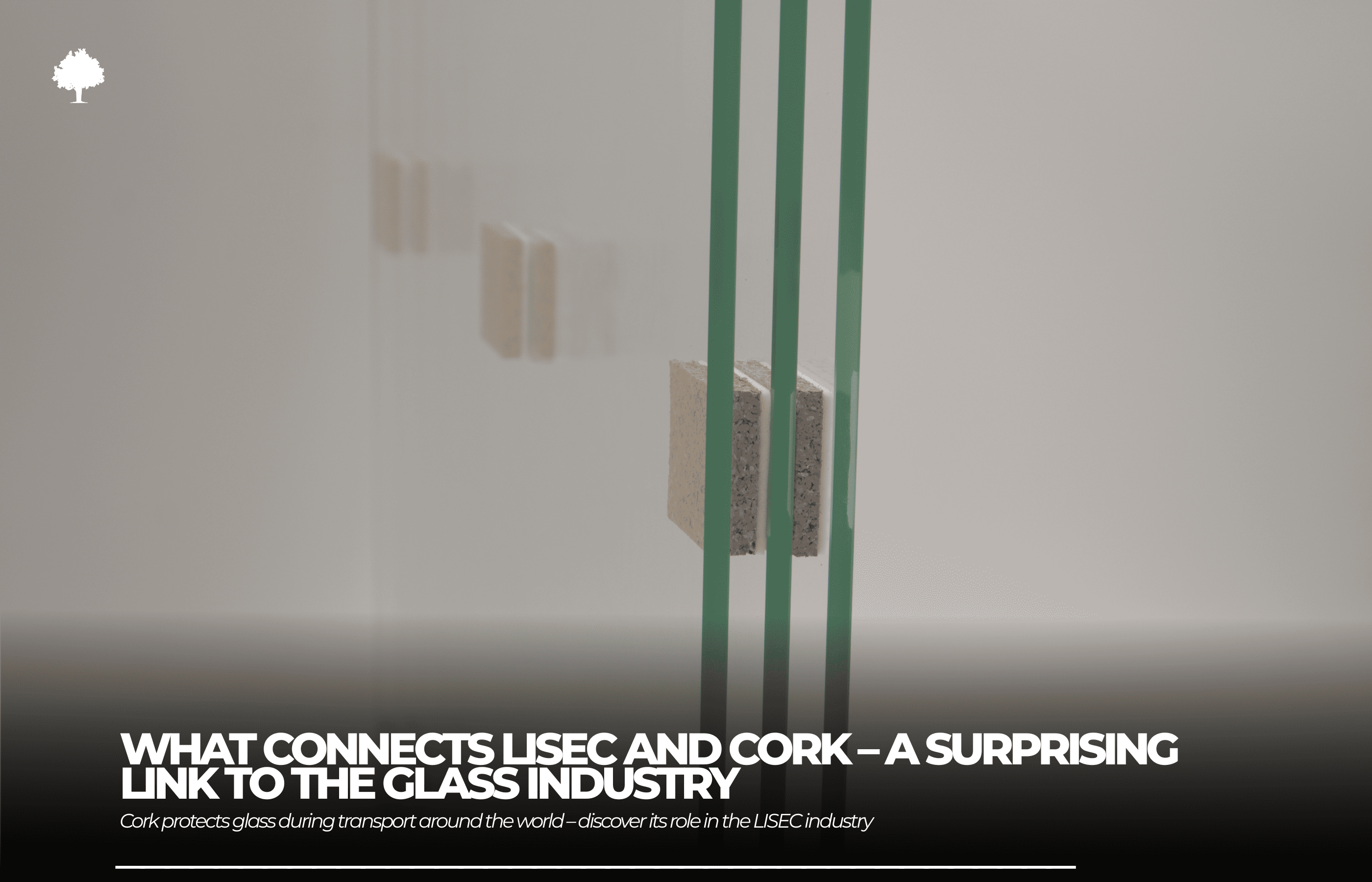

The answer to these challenges lies in natural cork-foam tape—a compact yet powerful material that merges the natural flexibility of cork with the firm grip of foam.

Used alongside specialized cutting machines, this professional-grade tape allows for the creation of cork spacers in precise sizes. This ensures a faster, more consistent production process and guarantees components of excellent quality and finish.

The resilience of natural cork absorbs vibrations and distributes pressure evenly, protecting the glass surface from localized damage. Meanwhile, the foam layer adds stability and prevents sheets from slipping during transport or storage.

How natural cork-foam tape aligns with LISEC’s philosophy

At first glance, LISEC’s advanced production systems and natural cork-foam tape might seem unrelated—one is a product of high-tech automation, the other a simple mechanical safeguard. Yet both are driven by the same philosophy: automation, precision, and protection.

Automation, precision, and protection – shared principles

For decades, LISEC has been perfecting glass processing. Every machine, software module, and production system serves one goal—to reduce the margin of error and ensure consistent, repeatable quality. Natural cork-foam tape operates under the same logic. While it isn’t a digital solution, its purpose is equally precise—it prevents accidental damage during the stages beyond automation: packaging, transport, and storage.

One shared goal: flawless glass

In glass manufacturing, precision is everything. That’s why both LISEC and protective material producers pursue the same outcome—maintaining the perfection of each sheet. Automated cutting and edge finishing are only the beginning—protecting that work throughout handling and delivery is the next vital step.

By combining LISEC’s advanced cutting technology with reliable protection materials such as natural cork-foam tape, manufacturers can significantly lower the risk of microcracks, scratches, and material waste. This approach makes glass processing more efficient and complete—covering the full journey of each pane, from the first cut to its delivery to the final customer.

Practical applications – where natural cork-foam tape makes a difference

While natural cork-foam tape may seem simple, its range of applications in the glass industry is impressively wide. It plays a vital role at multiple stages of production—from post-cutting operations to preparing finished glass for delivery.

Sorting and separation after cutting

After precise cutting, each glass panel must be individually separated and protected from direct surface contact. This is where natural cork-foam tape comes into play. With its flexibility and grip, the foam ensures the spacers keep sheets securely in place, preventing any movement or friction between them. As a result, the likelihood of microcracks or scratches—often unnoticed until later stages—is greatly reduced.

Protection after tempering

Once tempered, glass becomes extremely hard but also more vulnerable at its edges. Applying natural cork-foam tape provides safe handling and storage by cushioning vibrations and evenly distributing pressure along contact points. This is particularly crucial for large glass formats, where even the smallest impact can cause breakage.

Packaging and transportation

During packing and shipment preparation, natural cork-foam tape functions as a separator and stabilizer. Its structure maintains equal spacing between glass sheets, preventing movement inside transport frames or storage racks.

Storage and display

In many manufacturing plants, the tape is also used in warehouses and inspection areas, where glass is stored temporarily or displayed to clients. It enables safe stacking of sheets without the risk of scratching or damaging surfaces.

Why quality investment pays off

Reduced complaints and production waste

Using proper protective materials drastically reduces the risk of scratches, fractures, and other imperfections that often appear after the glass reaches the customer. Consequently, the number of complaints drops, as do the costs of replacements and re-manufacturing. Effective protection means not only safeguarding glass but also preserving the manufacturer’s reputation.

Improved appearance and product quality

High-end glass must be both durable and visually immaculate. Even the smallest blemish or scuff can determine product acceptance. Natural cork-foam tape, with its clean, residue-free removal and soft texture, keeps glass perfectly smooth from processing to final installation.

Enhanced safety during storage and transit

Transporting and storing glass are some of the most demanding steps in production. Vibrations, impacts, and temperature shifts can all threaten its integrity. By using the right separators—like natural cork-foam tape—manufacturers can significantly reduce the risk of damage, ensuring even large glass panels travel safely. This translates into real logistics savings and fewer material losses.

Summary

At first glance, natural cork-foam tape and LISEC’s high-tech systems may appear to belong to separate worlds—one symbolizes advanced automation, the other a straightforward protective solution. Yet, both share the same foundation: glass and the pursuit of perfection.

For decades, LISEC has led the glass industry by providing equipment and software that guarantee precision, process consistency, and operational safety. At the same time, natural cork-foam tape—humble in form yet essential in function—completes this process chain by protecting the results of both machine precision and human craftsmanship, ensuring each glass sheet reaches its destination in flawless condition.

FAQ

1. Why is natural cork-foam tape crucial in the glass industry?

It’s a small yet essential component that combines the cushioning power of natural cork with the grip of foam, preventing glass sheets from sliding or scratching during handling, storage, and transport.

2. How does natural cork-foam tape reflect LISEC’s approach?

LISEC stands for precision, automation, and quality assurance—values mirrored in natural cork-foam tape. Both share a common objective: maintaining glass in perfect condition at every stage, from processing to delivery.

3. Is investing in natural cork-foam tape worthwhile?

Absolutely. It helps minimize complaints, reduce material losses, and preserve product aesthetics. Over time, this leads to measurable cost savings and strengthens the manufacturer’s image as a provider of premium-quality glass.

4. Where is natural cork-foam tape most commonly used?

It’s typically applied between glass sheets after cutting or tempering and during sorting, packaging, and transportation. It performs effectively in both small artisan workshops and large automated production facilities.

.png)